GAF Shingle Roofing

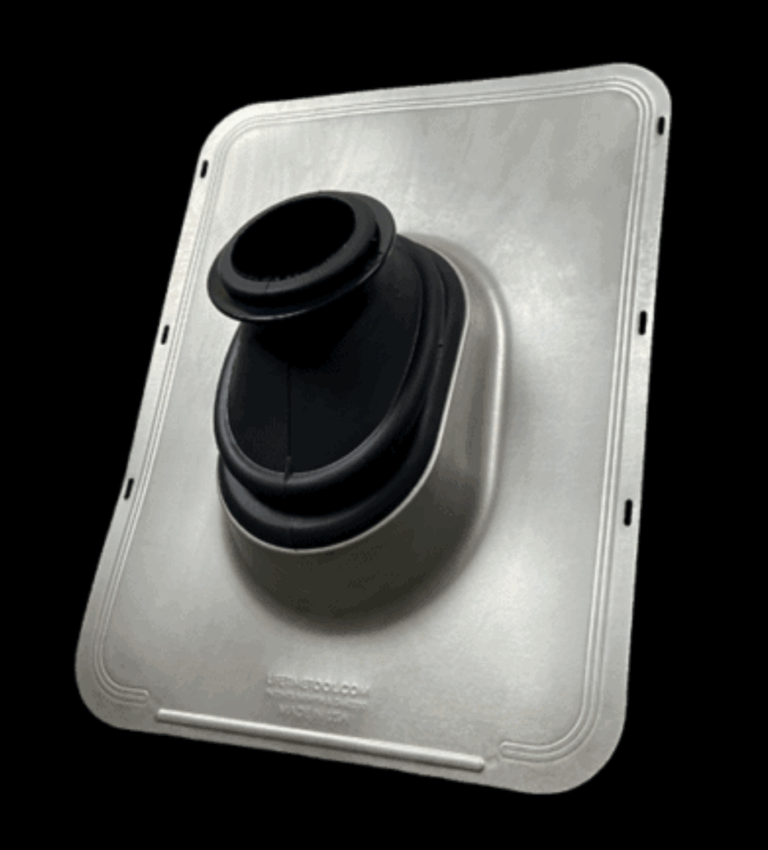

When getting a new shingle roof, it’s important to do it right. Our standard approach is to remove the old shingles and felt, replace any deteriorated decking, install drip edge if lacking or in poor condition, install new synthetic felt over the body of the roof (and ice and water shield and metal in the valleys), install GAF dimensional shingles using chalk lines for maintaining straight lines (California-cut style lay in the valleys), use new LifetimeTool.com boots (where customer budget allows) on pipe penetrations, and install GAF TimberTEX hip/ridge shingles with chalk lines and even exposure together with GAF Cobra3 shingle-over ridge vents. A key element of a professional installation is using a starter strip to protect the roof’s perimeter from wind uplift and ensure a clean, straight edge. Learn more about its benefits on our dedicated starter strip page.

We check ventilation requirements and sufficient soffit intake to meet code (300:1 and 150:1 attic square footage:net free ventilating area, balanced ~50%/50% soffit/ridges), and often install soffit vents in situations where it is insufficient. For shingle installation, the rubric is 6 nails per shingle, in the proper zone, and with proper pneumatic hose pressure for the nail guns (shingles often sag or fall off when roofers put 2–3 nails per shingle, place the nails above the zone/line, or drive them with too high an air pressure).

GAF Shingle Types

GAF (and most shingle manufacturers) offer three main lines:

- 3-tab: GAF Royal Sovereign

- Dimensional (Architectural): GAF Timberline HDZ

- Designer: GAF Grand Canyon, Camelot II, Woodland, Slateline

We consider GAF to offer the best quality shingles, in terms of long-lasting appearance, lower granule loss, and copper traces to mitigate black algae staining. We have seen how Tamko, Owens Corning, Atlas, and other brands age over 10–15 years, and GAF maintains great appearance for a longer time. We offer a 10-year proper-installation warranty against leaks in addition to the GAF limited lifetime material warranties.

Installation Details

Boots, chimneys, valleys, dormers, and other such penetrations are generally where a roof will deteriorate or leak first. We take care to address these weak points with additional steps of protection, including a standard use of ice and water shield around chimneys, boots, dormer sidewalls, and other penetrations.

For sidewalls, it is crucial to bring the flashing past the wall 2–4″, and also to ensure that the inner cigar roll (water stop) bend, under the shingles, is not flattened by stepping on it or from factory over-bending.

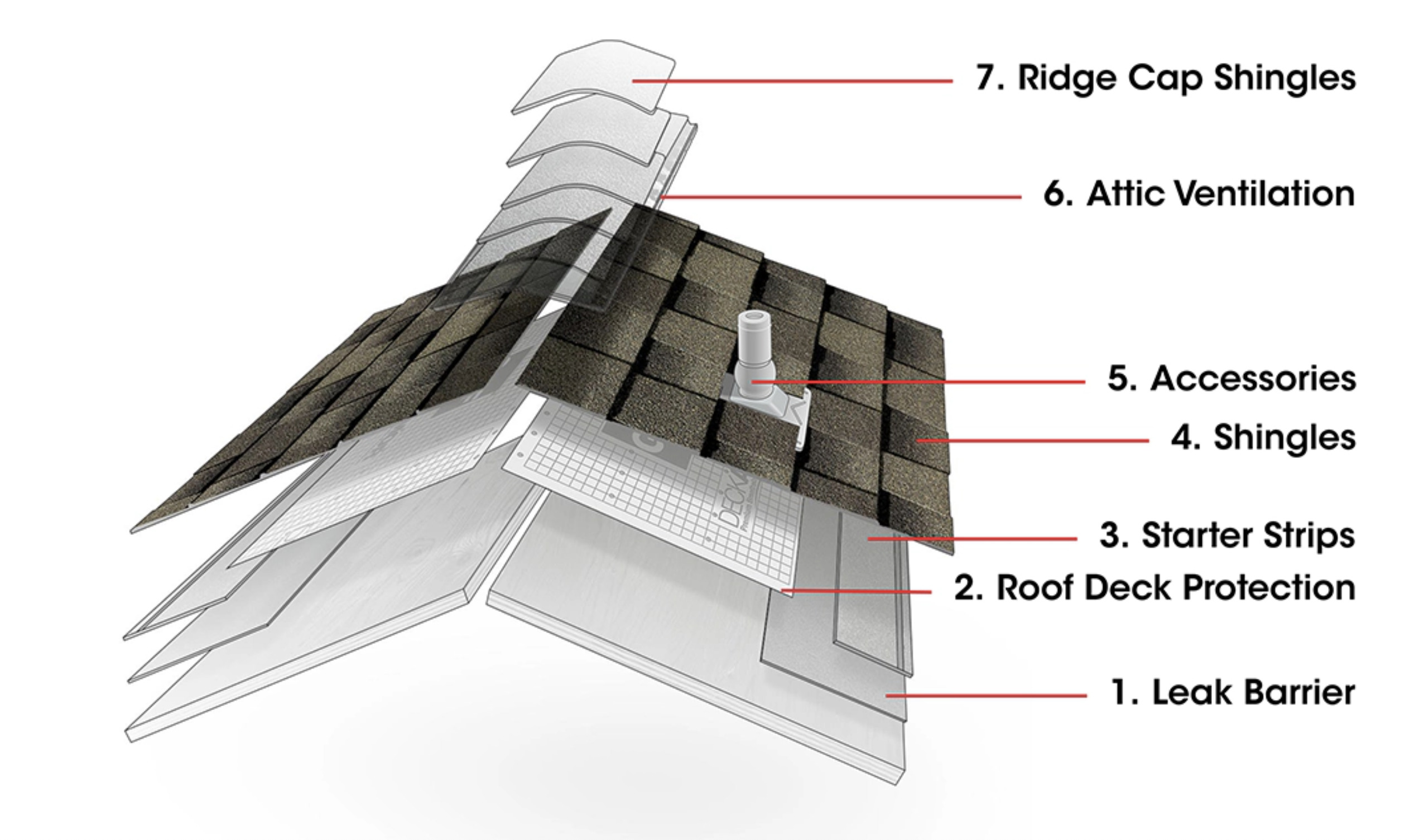

The figure below, taken from GAF, displays components of our typical roof system, although leak barrier is only required in valleys in our locality, not on eaves/rakes as depicted.

Get an Estimate

Give us a call if you are interested in getting a reroof, we’d love to get you an estimate! 334.332.7799