The Lost Art of Hot Tar and Asphalt Built-Up Roofs

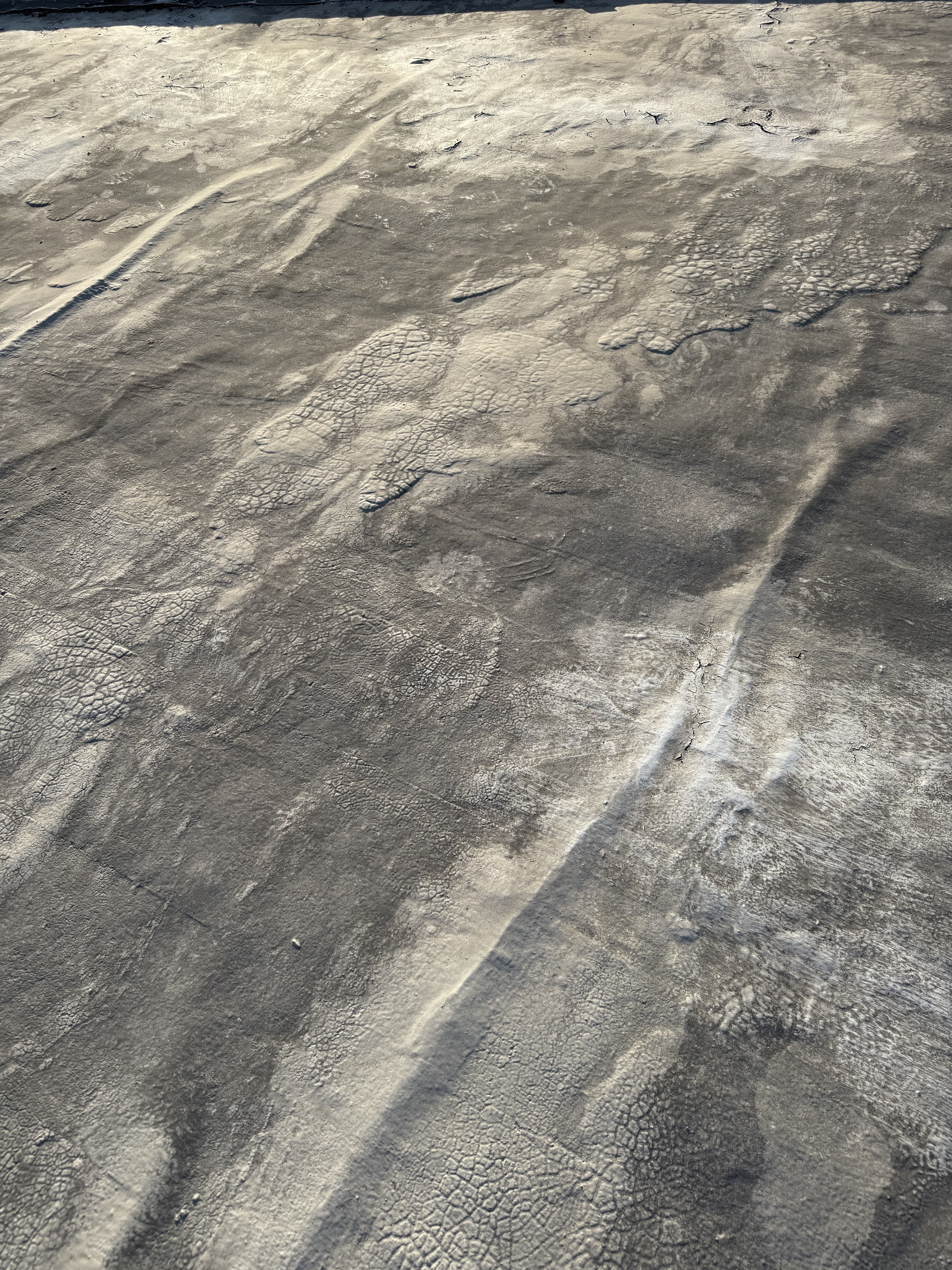

Built-up roof above from Roofer's Coffee Shop. In the world of commercial flat roofing, there are materials that are simply installed, and then there are materials that are an art form. Before the modern era of lightweight plastics, the old way was the heavy, messy, and brutally hot process of building a roof by hand, layer by layer, with a substance most people know only by a pungent smell: hot tar.

This isn't a sales pitch for a product we sell. It's a look back at a roofing system that was so effective, so durable, and so incredibly cheap that it puts our modern, high-tech alternatives to shame on one key metric: longevity-adjusted cost. We jettisoned from this roofing method not because it failed, but because its hidden costs—to human health and the environment—were simply too high.

Get a free, no-pressure inspection and quote for a modern solution → 334-332-7799

The Raw Materials: From Waste Products to Roofs

In the early to mid-20th century, the genius of the built-up roof was that its main components were not purpose-built products, but rather waste from other large industries. This made them incredibly cheap and abundant.

Coal tar pitch was a byproduct of the coal industry, specifically the process of heating coal in an oxygen-free environment to produce coke for the steel industry. This distillation created a thick, black, viscous liquid. The liquid was then cooled and processed into solid blocks or drums for transport to the job site.

Similarly, asphalt was a low-value residue from the refining of crude oil. It was a leftover from a much more profitable process. Like coal tar, it was packaged and transported as a solid block.

Even the final ballast layer of gravel was a low-cost, readily available material. The genius of these roofs lay in their use of "freebies"—the byproducts and natural materials that would have otherwise been disposed of—to build essential infrastructure. This directly contributed to the affordability of construction and, in a very real way, helped to fight the povertization of society by keeping costs low and jobs plentiful.

A Deeper Dive: Coal, Oil, and Creosote

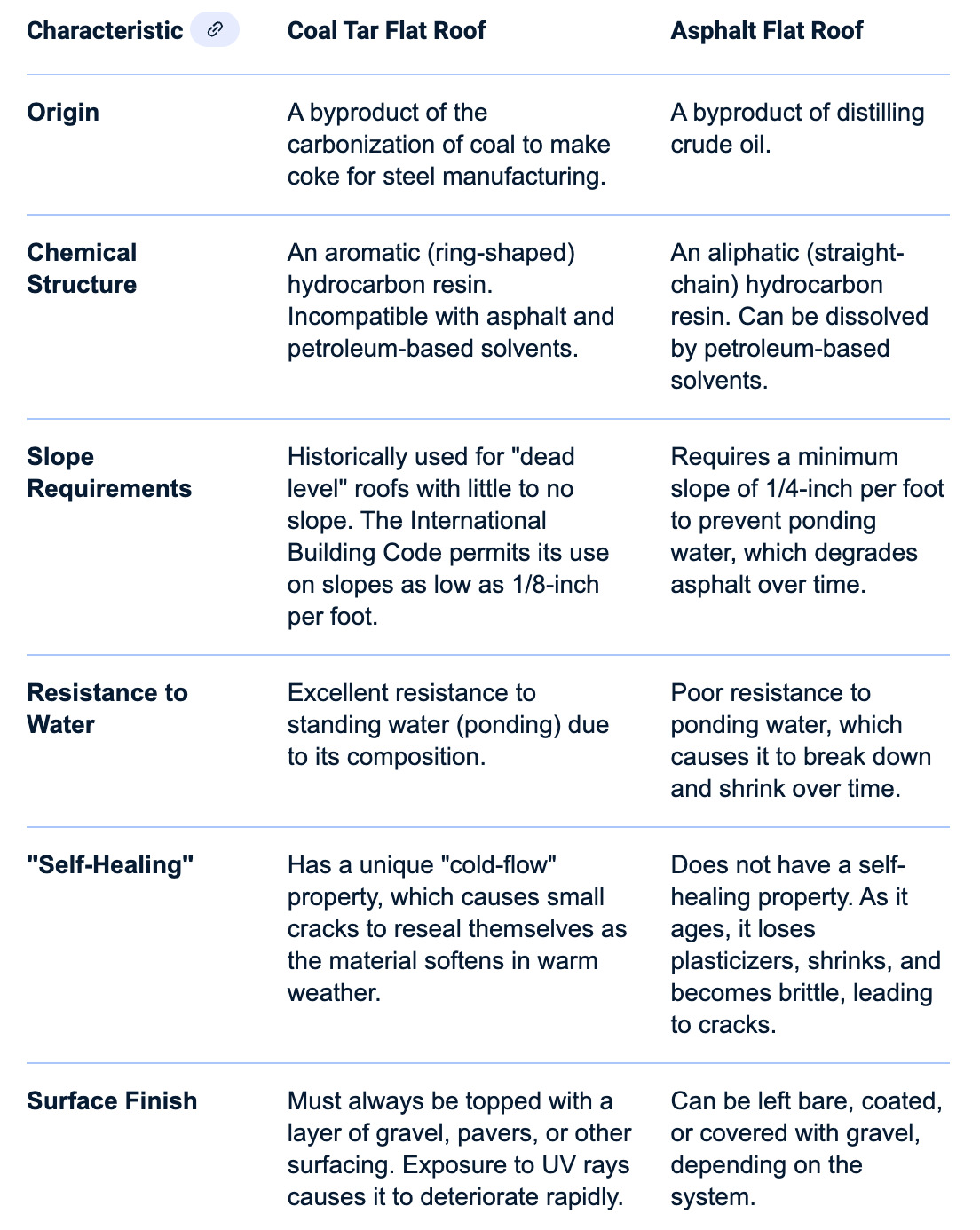

The difference between the old roofing materials goes beyond just tar and asphalt. It comes down to their very chemical origin. Bitumen, which we know as asphalt, is an oil-based product—a byproduct from the distillation of crude oil. It is chemically distinct from coal tar, which is a coal-based byproduct from the creation of coke.

This distinction is also seen in creosote, which comes in two main forms:

- Wood-tar creosote: Produced by heating wood in the absence of oxygen.

- Coal-tar creosote: Produced by heating coal in the absence of oxygen.

The process of heating in the absence of air is the common theme for these heavy, durable substances. However, the key difference lies in their final chemical makeup. The coal-derived products, like coal tar pitch and coal-tar creosote, are significantly more toxic due to a much higher concentration of polycyclic aromatic hydrocarbons (PAHs). This is the primary reason the industry moved away from them.

A Look into the Old Way: The Built-Up Roof (BUR)

A Built-Up Roof, or BUR, was exactly what it sounds like. It was a roofing system built in place on the rooftop, one layer at a time. The main components were simple: a roll of fibrous felt and a kettle full of liquid asphalt or coal tar pitch.

The process was an impressive feat of physical labor and skill. Solid blocks of pitch or asphalt were hoisted to the roof and melted in a large, heated kettle to over 400°F. Roofers would then haul the hot, viscous liquid across the roof in buckets. They would use a long-handled mop to spread the molten tar in an even coat, immediately followed by another crew member unrolling the felt directly into the hot liquid. The felt would be pressed into the tar, and the next layer would be installed with a strategic 12-inch offset, creating a seamless, multi-ply, and incredibly robust membrane.

The final touch was a "flood coat" of hot tar, which was then covered with a layer of gravel or crushed stone. This ballast wasn't just for looks; it served a crucial purpose, protecting the underlying membrane from the sun's damaging UV rays and holding the entire system in place against wind uplift. Kevin Ochis here sings the praises of coal roofs, providing some necessary backdrop against the overwhelming hate this product typically gets today. The fact is, nothing in today's market can touch the dirt-cheap, 40-year flat-roof lifespan, and incredible ponding-water leak-proofing, of self-healing coal roofs, despite their admitted downside dangers.

How to Identify Your Old Roof: Coal Tar vs. Asphalt vs. Butyl Rubber

While only a roofing professional can give you a definitive answer, you can get a good idea of what's on your roof by using a few simple, and safe, tests.

Before you begin, remember that older roofs, especially those from the era of coal-tar pitch, may contain asbestos. This is a serious health risk. If you suspect your roof contains this material, do not disturb it.

The Mineral Spirits Test

This is one of the safest and most reliable field tests you can perform. Simply get a clean, small piece of the roofing material—a small chip of pitch or a sliver of the membrane—and place it in a glass jar with some mineral spirits.

- Coal-Tar Pitch: The mineral spirits will dissolve the pitch and turn a distinct reddish-brown or amber color. This is a clear indicator of coal-tar pitch.

- Asphalt: The mineral spirits will dissolve the asphalt and turn a dark brown or black color. It's often a much murkier and less vibrant color than the coal-tar test.

- Butyl Rubber: This material will not dissolve in mineral spirits, and the liquid will remain clear.

The Smell Test

The odor of these materials is a key indicator, but it’s not always a definitive test, especially if the roof has been exposed to the elements for a long time.

- Coal-Tar Pitch: The smell is very strong and distinct, often described as a pungent, acrid, or "creosote-like" smell similar to that of telephone poles or railroad ties.

- Asphalt: The smell is much milder and more oily, like fresh asphalt on a road.

- Butyl Rubber: This material has a faint, rubbery or slightly solvent-like smell.

Pliability and Texture

How the material feels and acts when manipulated is another good clue.

- Coal-Tar Pitch: This material is typically much more brittle, especially on a cool day. It will crack and break more easily.

- Asphalt: Asphalt is more flexible than coal-tar pitch. It can be bent and will show some elasticity.

- Butyl Rubber: Butyl is very flexible, feeling almost like a thick inner tube. You can fold it and stretch it without it cracking.

The video Coal tar pitch V. Asphalt roof test demonstrates a field test for identifying the difference between coal tar pitch and asphalt roofing.

The Miracle Material: Coal Over Oil – Why Coal-Based Roofs Lasted for Decades

The remarkable durability of these old roofs was largely thanks to the properties of coal tar pitch. It had a unique quality that modern membranes can only dream of: a "self-healing" ability, making coal-roofs perfect for standing water (oil-roofs aka asphalt degrade in standing water and will leak).

When a coal tar roof got hot in the sun, the pitch would soften and begin to flow, sealing any small hairline cracks that had formed. This allowed the roof to effectively repair itself on a daily basis, which is why a well-installed coal tar roof could last for 40, 50, or even 60 years with minimal maintenance. These roofs were so resilient that they were a top choice for commercial buildings with flat surfaces and standing water, a condition that spells disaster for almost any other roofing material.

The Dangers of Overlaying Old Coal-Tar Roofs

When PVC, TPO, or even modern liquid coatings are installed over an old coal-tar pitch roof, it creates several serious hazards. The new membrane or coating acts as a vapor barrier, trapping the carcinogenic fumes from the coal-tar below. This can cause the fumes to build up and become concentrated, posing a significant risk to anyone who has to access the roof later for a repair or a full tear-off.

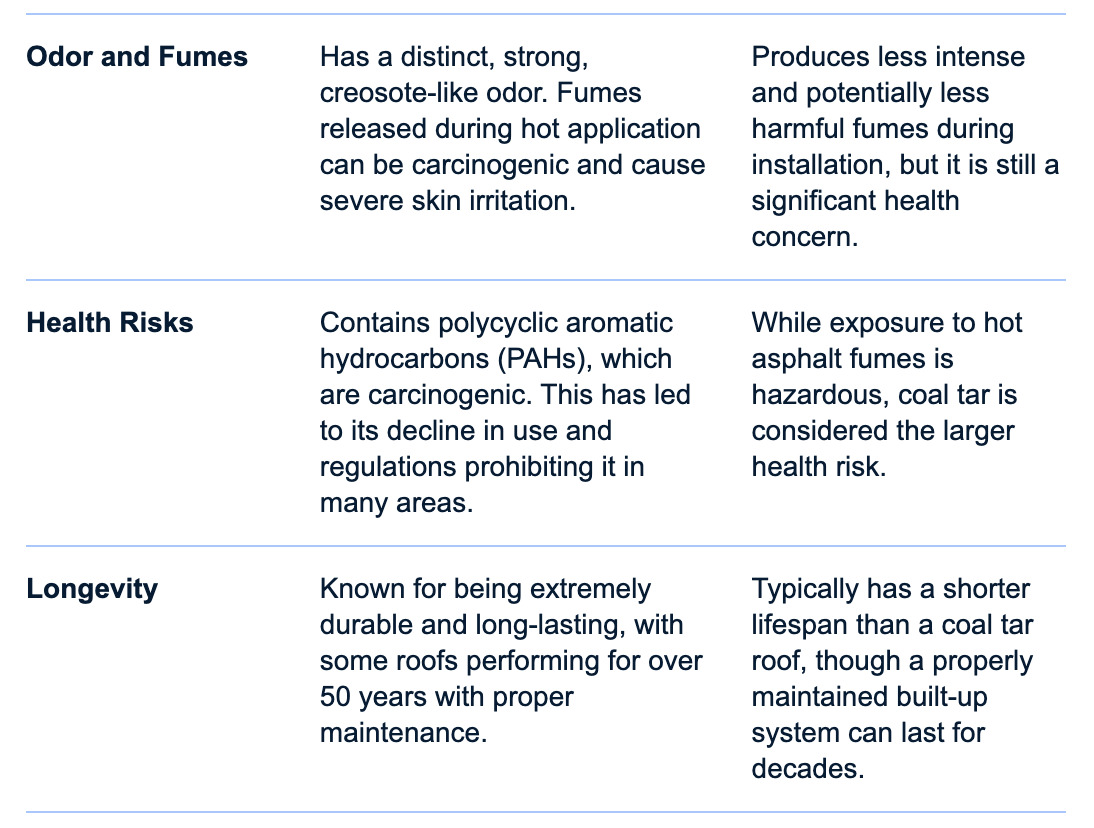

Additionally, the oils and chemicals in the old coal-tar are a prime cause of chemical incompatibility. They can cause the new material to prematurely break down, leading to rapid system failure. This is often caused by the underlying coal tar, which shows signs of alligatoring—a specific pattern of cracking and aging that looks like alligator scales. Alligatoring forms on coal tar because of two main processes: oxidation and the loss of volatile oils. Over time, the sun's powerful UV rays and heat cause the material to oxidize and dry out. As the surface shrinks and cracks faster than the material underneath, it forms the distinctive, scaly pattern. A new material cannot properly adhere to this unstable surface.

This chemical incompatibility is a different issue from normal blistering, where trapped moisture or air expands from the heat of the sun and creates bubbles under the surface.

A full tear-off and replacement is the only safe and effective solution. Trying to save money by adding a new layer over a coal-tar pitch roof creates a much more dangerous and costly problem in the long run.

A Viable Solution for Aging Old Coal-Tar Roofs: The Sealed DensDeck & PVC Overlay

While a full tear-off is always the safest option, there are instances where an overlay is necessary. This can be done safely by installing DensDeck, a gypsum board, with sealed edges and a mechanically attached PVC membrane over the old coal-tar pitch roof.

This method is a common and effective solution because it creates a complete separation between the old coal-tar and the new PVC system. The key benefits are:

- Vapor Barrier: The DensDeck and its sealed edges act as a robust vapor barrier. This prevents the carcinogenic fumes from the coal-tar from off-gassing and becoming trapped under the new membrane.

- Chemical Barrier: It also provides a physical barrier, preventing the volatile oils in the coal-tar from chemically reacting with and degrading the new PVC membrane from below. This eliminates the risk of premature failure.

- Smooth, Stable Surface: The DensDeck provides a new, smooth, and stable surface to attach the new membrane. This is crucial because old coal-tar roofs are often uneven and can show signs of alligatoring, which makes proper adhesion and mechanical attachment difficult.

- Mechanical Attachment: By using a mechanically attached system, the new membrane is secured directly to the deck through the DensDeck, rather than relying on adhesives that might fail due to the chemical incompatibility of the underlying coal-tar.

This method allows for the safe installation of a new, durable roofing system without the significant cost and safety risks associated with a complete tear-off of the old coal-tar roof. It's an excellent way to balance safety, longevity, and cost.

The Unspoken Cost: A Reckoning of Safety, Health, and the Environment

So, if hot tar was such a durable and economical material, why did we stop using it? The answer lies in the unacceptable risks associated with the material and the installation process.

The Human Cost: Toxic Fumes and Cancer

This is the number one reason. Heating coal tar pitch to over 400°F releases a complex cocktail of airborne chemicals, most notably polycyclic aromatic hydrocarbons (PAHs). These compounds are known carcinogens and pose a severe health risk to the roofers who are exposed to them all day, every day.

A simple mask or respirator is not enough to protect a roofer. The most effective equipment would be a positive-pressure supplied-air respirator—a helmet connected to a clean air source. This is simply not a practical solution for a roofer's job, which is why we had to abandon the material.

The Environmental Impact

While coal tar was a byproduct of the coal industry, its environmental footprint was far from benign. The high concentration of PAHs in the material meant that over decades, it would leach into the ground from storm runoff, contaminating the surrounding soil and water table.

The Economic Shift: PVC vs. The Old Guard

The roofing industry's shift from tar to modern membranes like PVC represents a complete change in the economic model.

Let's look at the numbers again, adjusting for inflation and the lifespan of the roofs. We'll use a conservative lifespan of 40 years for the old tar roof (a real-world example) and 25 years for a modern PVC roof (a generous estimate for a typical installation).

| 1940s Coal Tar BUR | Modern PVC Membrane | |

|---|---|---|

| Initial Cost (in today's dollars) | ~$2.10/sq ft | ~$14.00/sq ft |

| Expected Lifespan | 40 years | 25 years |

| Cost Per Year of Service | $0.0525/sq ft | $0.56/sq ft |

As the numbers show, a modern PVC roof is 10 times more expensive per year of service than a coal tar roof. This isn't just a slight price increase; it's a completely different value proposition. The old system was built on low-cost re-purposed products. The new system is built on high-cost, manufactured materials with nice, but extremely costly, safety improvements (less chance of fire burning building down, carcinogens, heat burns to workers).

The New King Has Its Flaws: The Hidden Dangers of PVC

PVC is a fantastic material—durable, reflective, and with a long lifespan. But it's not without its own risks, and it would be dishonest to give it a free pass just because it's the modern standard. The key danger with PVC lies in its installation, specifically during heat welding.

When PVC is heated to over 1,000°F (538°C) to create a perfect seam, it can release small amounts of hydrogen chloride gas (HCl). This is a highly irritating and corrosive gas. While it's not a carcinogen like the PAHs from hot tar, it can still cause severe irritation to the eyes, skin, and respiratory tract. Proper ventilation and personal protective equipment are still required to ensure a safe installation.

Conclusion

Ultimately, the built-up roof, with its kettle, mop, and gravel, is an incredible chapter in roofing history. It was a testament to the idea that a simple, heavy-duty system could deliver unmatched longevity and value. We have moved on to safer materials, but the trade-off has been a significant increase in cost and a completely new set of challenges for both roofers and their customers.

Get a free, no-pressure inspection and quote for a modern solution that works for you → 334-332-7799